The BuildBlock Design

The creation of BuildBlock forms was focused on solving problems encountered when building ICF structures both simple and complex. BuildBlock introduced many patented features providing real practical benefits for the installer and owner. Some of those features included:

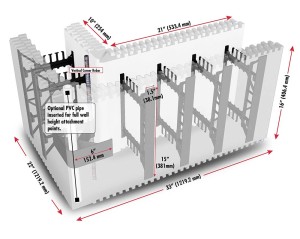

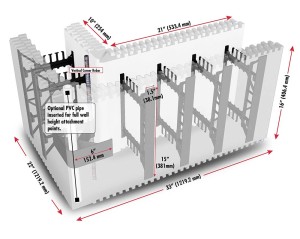

- a numbered measuring system embossed on the forms face eliminating the need to measure a form before cutting;

- horizontal cut lines every two inches over the height of the form to facilitate cutting in window bucks without needing a level;

- High density hard attachment points marked with BB, built into the web flange for attaching bracing and heavy objects with pull strengths exceeding 450 lb. screw extraction pressures;

- Web rebar fingers that would lock two steel rebar down positively in multiple locations allowing the proper flow of concrete during the pouring process;

- a strong web that had 8 inch spaced web cross bars so a block could be cut in half allowing each half block to maintain the same strength both top and bottom eliminating the need for half height specialty blocks.

Other Benefits

- The BuildBlock ICF web also uses saddles in the center portion of each web for setting steel to eliminate obstruction of concrete flow during the pour process.

- Longer corners and 45 degree corner forms with full width connection fingers eliminate corners from pulling away from wall sections during the pour process as well.

- Other forms often require additional accessories to obtain what the BuildBlock form does by itself.

- The form connections are the full width of the foam thickness, unlike other forms that often must be glued to prevent them floating or coming apart, totally eliminated this need in most circumstances saving additional foam expense and labor.

- BuildBlock Forms were designed on a 6 inch web spacing making them one of the strongest forms on the marketing and providing additional attachment points for bracing and finishes.

- All BuildBlock forms are fully reversible eliminating the need for left and right corners and allowing much faster installation times.

- One-inch vertical cut lines with a one inch repeating cut pattern eliminating foam waste in every cut (allowing waste of 1% or less) giving the designer and installer the most versatile value-added ICF form on the market today.

BuildBlock strives to manufacture the finest, most value oriented form in the marketplace, building one of the strongest distribution and manufacturing companies along the way. BuildBlock introduced the industry’s first on-line ordering system allowing customers to order products at their convenience, while also developing a unique master distributor program with protected territories. Each year BuildBlock increases its manufacturing locations. Currently there fourteen locations in the North America.

More locations provide shorter shipping distances and lower the delivered form costs to our distributors and customers. It further increased its distribution with foreign licensing of its products around the world and opened its first foreign facility in Egypt in 2012 making BuildBlock truly an international form company. BuildBlock has added western Canada and Mexico facilities since then and continues to expand. BuildBlock has additional licensees around the world including Cyprus and the Philippines.

BuildBlock has continued to evolve its product line including versatile and very affordable BuildDeck floor and roofing system, BuildLock Knockdown 4-12+ inch products, and GlobalBlock the first fully reversible all foam ICF. Additional ICF accessories such as BuildBrace an ICF bracing and alignment system, BuildCrete Stucco & Plaster finishes, ThermalSert Insulation Inserts, and BuildClip an optional reinforcing clip strengthening cut blocks as they’re integrated into a flooring systems are added to solve needs in the market today.

The future is very bright for BuildBlock distributors and customers. In the years ahead BuildBlock is the company to watch for innovation and growth in this exciting industry that is changing how buildings are built for today for the future. Build your future today. “Build It Once Build It For Life”